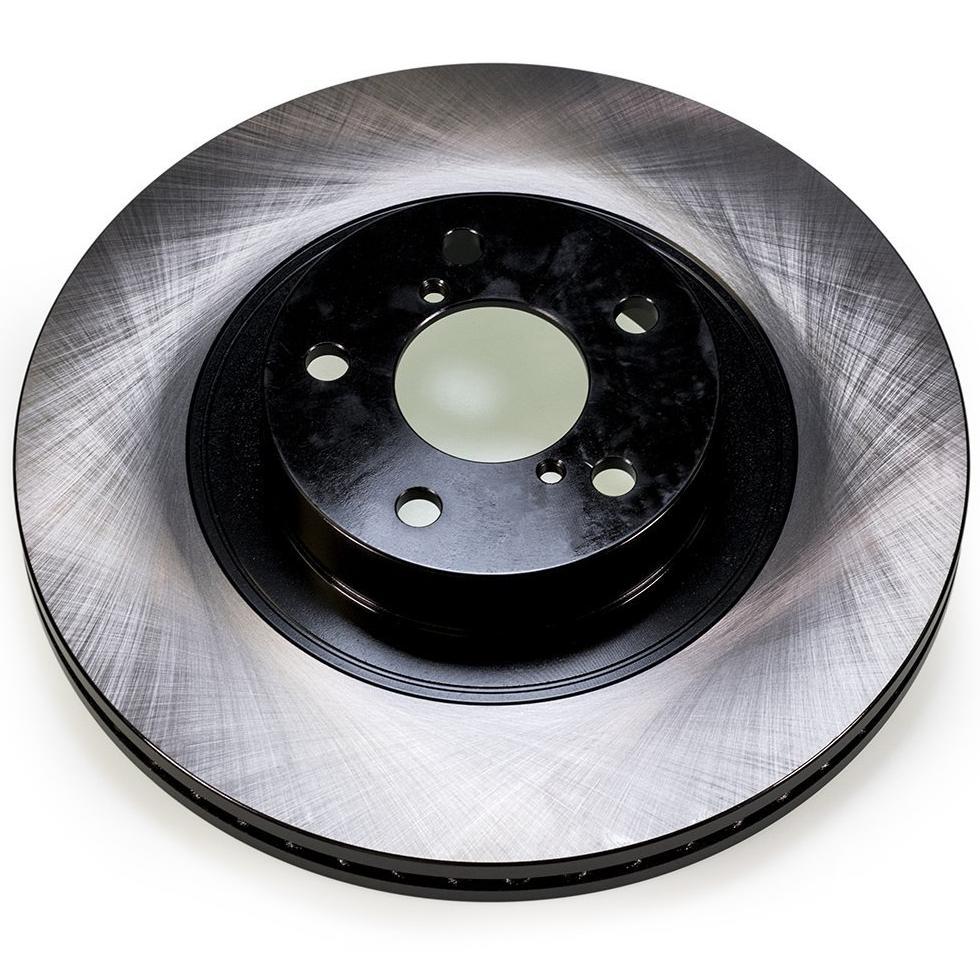

Centric Premium High Carbon Front Brake Rotor (Evo 8/9)

SKU:sto125.46064

Order and get 284 reward points

Earn points by signing up for our rewards program

Centric Premium High Carbon Front Brake Rotor (Evo 8/9)

Centric Premium High Carbon Front Brake Rotor

As drivers work on improving their engine’s ability to accelerate with more power and speed, they need brakes that can stop a car just as well.

Centric’s Premium Front Brake Rotors are some of our favorites for the Mitsubishi Evo 8 and 9. Built to handle the heat of high-performance driving and repeated stop situations, Centric’s brakes in its 125 series are made with advanced metallurgy — its custom molybdenum and chromium alloys are resistant to rotor cracking and improve brake performance, and higher concentrations of carbon and chromium resists oxidation more than other rotors.

The rotors are double ground on the disc, which eliminates thickness and variations, and leaves behind a non-directional finish, reducing the break-in time. Each rotor is equipped with a directional vane design for improved airflow and cooling, and is covered with its Black E-Coat anti-corrosion coating on non-friction surfaces to further reduce the wasting away of normal use.

Centric’s premium brake rotors are an important upgrade for your Evo 8 or 9. With all the work you put in for speed, the ability to slow down will become doubly important.

Please note: These rotors are sold individually

Applications

- 2003-2006 Mistubishi Evo 8/9

What's in the box?

- (1) Front Brake Rotor

Warranty

- MFGR. Limited Warranty

- Center split castings for Increased strength and stability

- Directional vane designs provide improved airflow and cooling

- Black E-Coat anti-corrosive coating protects the cooling vanes and mounting surfaces from rusting prematurely

- Double disc ground friction surface finish

- Mill balancing ensures smooth operation at all speeds

Centric parts High Carbon Brake Rotors feature a double disc ground finish which virtually eliminates run out and any disc thickness variation issues. Double disc grinding also produces a non-directional finish for improved rotor and pad break-in.

Centric Parts High Carbon Brake Rotors feature our exclusive black E-Coating on all non-friction surfaces. E-Coating is an advanced electro-statically applied finish that has been engineered to withstand 400 hours of salt spray testing without corroding.

Centric Parts High Carbon Brake Rotors utilize the same split core symmetric molding process used by OE manufacturers. Rotors with symmetric core molding dissipate heat more efficiently and provide better stopping power especially in repeat stop situations.

Please note: These rotors are sold individually