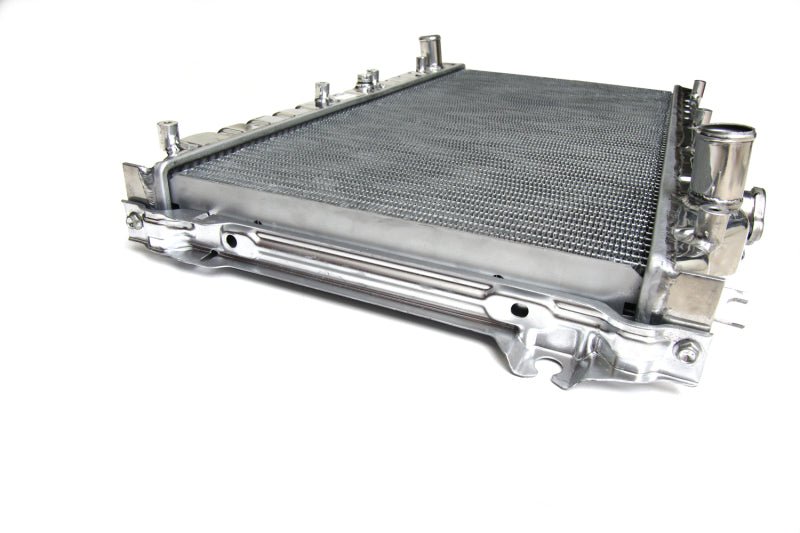

CSF Radiator (89-97 Mazda Miata)

SKU:CSF2862

Order and get 630 reward points

Earn points by signing up for our rewards program

CSF Radiator (89-97 Mazda Miata)

CSF Radiator (89-97 Mazda Miata)

CSF manufactures the most advanced and efficient radiator cores in the industry by using innovative tube and fin technologies with industry leading testing methods to maximize airflow and heat dissipation. These techniques allow CSF to stay ahead of the pack when it comes to radiator technology!

“B-Tube” technology – Unlike a regular oval shape “O” type radiator tube, CSF uses a specially engineered tube in a shape of a “B”. These “B-tubes” are carefully formed and then brazed over the seam to seal. CSF is able to use thinner and lighter aluminum material (better cooling efficiency) because this design is actually stronger than normal “O” shape tubes that are welded.

The design (inlet in the middle of tube that is seam brazed) increases the heat transfer surface area of the tubes by approximately 15% over regular tubes. You get the efficiency of 2 smaller tubes vs. 1 large tube within the same space criteria. With “B-tubes” you are able to get “dual liquid laminar flow.”

High Efficiency Multi Louvered Fin – CSF uses ultra efficient multi louvered fins that are carefully and precisely aligned to maximize airflow through each radiator core. Fin specifications are carefully measured and calculated for each application, and tested for maximum heat rejection efficiency in our wind-tunnel lab.

Each CSF high quality radiator is completed with an industry leading 1 hour, hand polished “Show-Stopper™ mirror finish.” Our hand polishing tools and techniques in our new polishing center located at the end of the production line ensures that every CSF cooling system looks just as good as it performs.

Features

- CAD/CAM designed using Unigraphics™ Software

- OE radial and deep drawn aluminum endtanks

- “B-Tube” Technology – Stronger, most efficient tube in the world

- Wind tunnel tested for optimal radiator core cooling efficiency

- “Racing Style” Aluminum Drain Plug

- Brazed in CAB Furnace

- ISO 9001/9002 certification

- Military Grade (special clad) aluminum used for tubes, fins, header, plates, and side brackets (JIS 3003 spec minimum)

- CNC machined fittings

- “Master Class” TIG welding

Applications

- 1989-1997 Mazda MX-5 Miata (NA)

What's In The Box?

- 1 - CSF Racing Radiator

Warranty

- Manufacturer Standard Warranty